Chain

We focus on basics of manufacturing chains to create a perfect product. Our basics details that a roller chain is used toconnect two sprockets together and transfer torque. Roller chain is made up of a series of inner and outer links connected to form a flexible strand. We build on our knowledge and expertise to further fortify precision and engineering. Eachof the singular parts is finely manufactured with superior quality and durability, right from the exceptional raw material orenhanced processes.

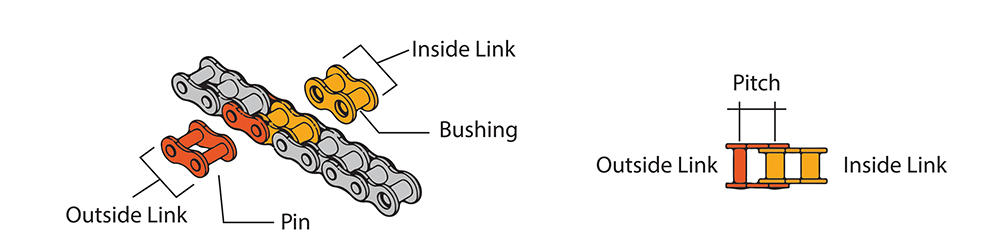

Outside Links consist of two outside plates which are connected by two pins that are pressed into each plate. The pins inthe outside link go through the inside of the hollow bushings when the inner and outer links are assembled. The pins canfreely spin on the inside of the bushings.

Inside Link consists of two inside plates that are connected by two hollow bushings which are pressed into each plate. Theteeth of the sprocket contact the surface of the bushings when the chain is wrapped around a sprocket. Pitch is the distance between the centers of two adjacent pins. Common pitches are 0.25”, known as #25, and 0.375” (#35).

A rider’s safety and comfort being the prime motive helps us manufacture the best product. Samples from the finished manufactured chains undergo rigorous testing in state-of-the-art testing labs for high speed and load to evaluate their performance and maintaining international standards. All the chains are pre-lubricated with special lubricants for ensuring long operational life.